-

Alumina Ceramic Components

-

Ceramic Housing

-

Metallized Alumina Ceramics

-

Custom Ceramic Parts

-

Alumina Ceramic Insulator

-

Alumina Ceramic Rings

-

Pressure Sensor Ceramic

-

Advanced Technical Ceramics

-

Advanced Engineering Ceramics

-

Fuse Ceramic

-

Ceramic Connector Blocks

-

Electronic Ceramic Components

-

Magnetron Ceramic

-

Zirconia Ceramic Parts

-

Alumina Ceramic Rods

-

Mr.FarnReply very fast and easy to talk!

Mr.FarnReply very fast and easy to talk! -

Mr.JacksonGood service and nice to talk.

Mr.JacksonGood service and nice to talk.

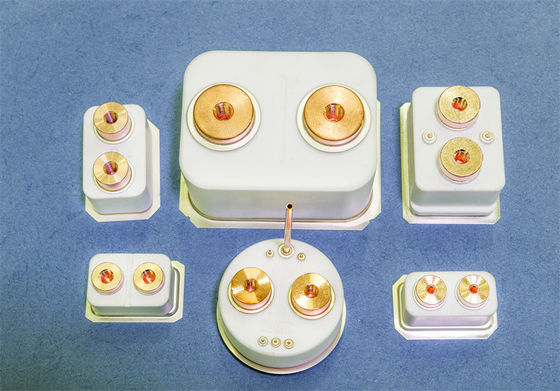

Custom Metallized Alumina Ceramics Brazing With Metal Parts Ceramic Relay

| Product Name | Metallized Alumina Ceramic Tube / Metallized Electrical Ceramic Components | Material | Alumina (Aluminum Oxide, Al2O3) |

|---|---|---|---|

| Insulation Resistance | 1000M Ω(1000VDC) | Thermal Shock Resistance Room Temperature To 850C | Will Not Burst Or Leak After Five Operations |

| Working Temperature | -40℃-125℃ | Operate Time | ≤30ms |

| Release Time | ≤10ms | Shock Resistance Functional | 196m/s² (20G Above) |

| Shock Resistance Destructive | 490m/s²(50G Above) | Helium Leak Rate | < 10-9 Cc/sec |

| Tensile Strength, Kovar Cup Method | > 20,000 Psi, Avg. (138N/mm2) | ||

| Highlight | Metallized Alumina Ceramics Relay,Custom Metallized Alumina Ceramic Relay,99% Metallized Alumina Ceramics |

||

Custom Metallized Alumina Ceramics Brazing With Metal Parts Ceramic Relay

1. Description:

Technical ceramics are difficult to bond to other ceramics or metal structures due to their strong ionic and covalent bonds. Fortunately, Precision Ceramics has years of experience using proven joining techniques to bond technical ceramics. The technique used to join the ceramic is typically chosen depending on the specific requirements of the joint and how difficult it is to create.

2. Feature Advantages:

1) Impact resistance

2) High welding sealing performance

3) High hardness and high density

4) Good insulation performance

5) High temperature resistance

6) A variety of specifications is available

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Printing --- Nickel Plating --- Assembing --- Brazing --- Inspecting --- Packing

![]()

6. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

![]()

7. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

![]()

8. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service

![]()

9. Shipping and Package:

![]()

Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!

Loudi Antaeus Electronic Ceramic Co.,Ltd

Factory address:Loudi Economy and Technological Development Zone,Hunan,China.

Contact person:Alice Deng

Tel:+8615073852630 (wechat)

Mail: alice@andidz.com

Skype: alicedeng0629