-

Alumina Ceramic Components

-

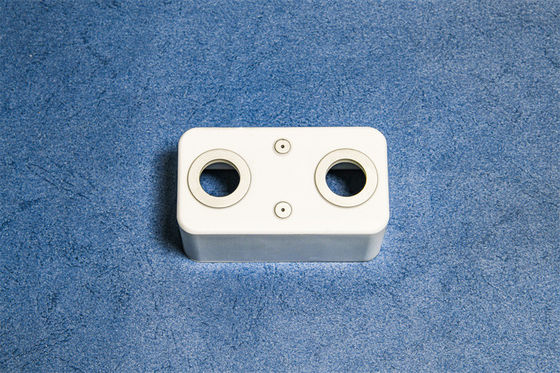

Ceramic Housing

-

Metallized Alumina Ceramics

-

Custom Ceramic Parts

-

Alumina Ceramic Insulator

-

Alumina Ceramic Rings

-

Pressure Sensor Ceramic

-

Advanced Technical Ceramics

-

Advanced Engineering Ceramics

-

Fuse Ceramic

-

Ceramic Connector Blocks

-

Electronic Ceramic Components

-

Magnetron Ceramic

-

Zirconia Ceramic Parts

-

Alumina Ceramic Rods

-

Mr.FarnReply very fast and easy to talk!

Mr.FarnReply very fast and easy to talk! -

Mr.JacksonGood service and nice to talk.

Mr.JacksonGood service and nice to talk.

High Voltage Relay Metallized Brazing Alumina Ceramics 3.9g/Cm3 For EV Car

| Product Name | Relay Metallized Alumina Ceramic / Ceramic DC Contactor | Material | Alumina (Aluminum Oxide, Al2O3) |

|---|---|---|---|

| Insulation Resistance | 1000M Ω(1000VDC) | Dielectric Strength | 3000VAC 1 Min |

| Working Temperature | -40℃-125℃ | Operate Time | ≤30ms |

| Release Time | ≤10ms | Shock Resistance Functional | 196m/s² (20G Above) |

| Shock Resistance Destructive | 490m/s²(50G Above) | Humidity | 5~85%RH |

| Virbration Resistance | 10-200HZ,49m/s² | ||

| Highlight | Relay Metallized Brazing Alumina Ceramics,Alumina Ceramics 3.9g/Cm3,EV Car Metallized Alumina Ceramics |

||

High Voltage Relay Metallized Brazing Alumina Ceramics 3.9g/Cm3 For EV Car

1. Description:

Technical ceramics tend to be excellent electric insulators (high dielectric strength). They are especially useful in high-temperature applications where other materials’ mechanical & thermal properties tend to degrade. Some ceramics have low electrical loss & high dielectric permittivity; these are typically used in electronic applications like capacitors and resonators. Additionally, the ability to combine an insulator with a structural component has lead to many product innovations.

2. Feature Advantages:

1) High hardness and high density

2) Low thermal conductivity

3) High welding sealing performance

4) Good insulation performance

5) High temperature resistance

6) Satisfy various technical requests

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Printing --- Nickel Plating --- Assembing --- Brazing --- Inspecting --- Packing

![]()

6. Application Fields:

Widely apply for new energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

![]()

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

![]()

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

![]()

9. Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!