-

Alumina Ceramic Components

-

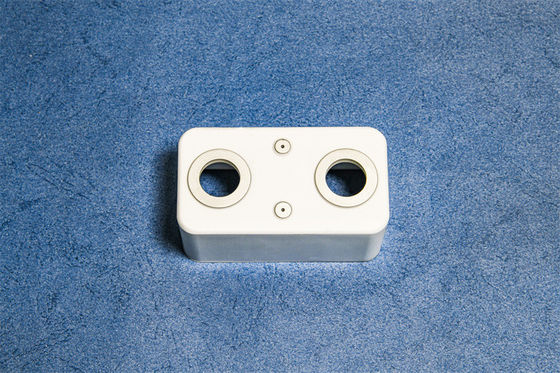

Ceramic Housing

-

Metallized Alumina Ceramics

-

Custom Ceramic Parts

-

Alumina Ceramic Insulator

-

Alumina Ceramic Rings

-

Pressure Sensor Ceramic

-

Advanced Technical Ceramics

-

Advanced Engineering Ceramics

-

Fuse Ceramic

-

Ceramic Connector Blocks

-

Electronic Ceramic Components

-

Magnetron Ceramic

-

Zirconia Ceramic Parts

-

Alumina Ceramic Rods

-

Mr.FarnReply very fast and easy to talk!

Mr.FarnReply very fast and easy to talk! -

Mr.JacksonGood service and nice to talk.

Mr.JacksonGood service and nice to talk.

High Precision Alumina Ceramic Components with Iatf16949 Ceramic Housing and Thermal Shock Resistance 250℃

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Breakdown Voltage | 20 KV/mm | Rohs Hardness | ≥85 |

|---|---|---|---|

| Usage | Iatf16949 Ceramic Housing | Form | Solid |

| Package | Carton | Volume Density | ≥3.65 |

| Hardness | 9 Mohs | Density | 3.9 G/cm3 |

| Highlight | Iatf16949 Ceramic Housing Alumina Ceramic Components,Thermal Shock Resistance 250℃ Alumina Ceramic Components,Tolerance ±0.02 mm Alumina Ceramic Components |

||

Product Description:

Alumina Ceramic Components offer a versatile solution for a wide range of industrial applications, characterized by their exceptional chemical resistance, high thermal conductivity, and superior mechanical properties. These components are primarily composed of Al2O3, commonly known as alumina, which is a highly durable material renowned for its excellent performance in demanding environments.

One of the key products within the Alumina Ceramic Components range is the Alumina Ceramic Ring. This precision-engineered component boasts a tolerance of ±0.02 mm, ensuring precise and reliable performance in various applications. With a density of 3.9 g/cm3, the Alumina Ceramic Ring offers a perfect balance between strength and weight, making it ideal for use in critical systems where durability is paramount.

Another essential product in this line is the Alumina Ceramic Pad, which shares the same exceptional characteristics as the Alumina Ceramic Ring. With a hardness rating of 9 Mohs, these pads exhibit outstanding resistance to wear and abrasion, ensuring long-lasting performance even in high-stress conditions. The polished surface finish of the Alumina Ceramic Pad not only enhances its aesthetic appeal but also improves its functionality by reducing friction and promoting efficient operation.

Alumina Ceramic Components are designed to meet the demanding requirements of modern industries, where reliability and performance are non-negotiable. Whether used in high-temperature environments, corrosive conditions, or heavy-duty applications, these components excel in delivering consistent results under challenging circumstances.

Thanks to their unique chemical composition and superior physical properties, Alumina Ceramic Components offer a cost-effective solution for various industrial needs. The high purity of Al2O3 ensures excellent chemical resistance, preventing corrosion and degradation over time. Additionally, the precisely controlled tolerance of ±0.02 mm guarantees a perfect fit and seamless integration into existing systems, reducing downtime and maintenance costs.

When it comes to durability and longevity, Alumina Ceramic Components stand out as a reliable choice for critical applications. The combination of high density and exceptional hardness (9 Mohs) makes these components resistant to extreme conditions, including high pressure, temperature fluctuations, and mechanical stress. This resilience translates into extended lifespan and reduced replacement frequency, resulting in overall cost savings for businesses.

Whether used as wear-resistant liners, insulating components, or structural supports, Alumina Ceramic Components offer unparalleled performance across a wide range of industries, including aerospace, automotive, electronics, and manufacturing. Their versatility and reliability make them a preferred choice for engineers and designers looking to enhance the efficiency and durability of their products.

In conclusion, Alumina Ceramic Components, including the Alumina Ceramic Ring and Alumina Ceramic Pad, represent a cutting-edge solution for demanding industrial applications. With their exceptional chemical ingredients, precise tolerances, high density, impressive hardness, and polished surface finish, these components deliver unmatched performance and reliability in challenging environments. Invest in Alumina Ceramic Components today to experience the benefits of top-quality engineering and innovation.

Features:

- Product Name: Alumina Ceramic Components

- Volume Density: ≥3.65

- Chemical Ingredients: Al2O3 Alumina Ceramic Components

- Thermal Shock Resistance: 250℃

- Breakdown Voltage: 20 KV/mm

- Package: Carton

Technical Parameters:

| Tolerance | ±0.02 mm |

| Hardness | 9 Mohs |

| Chemical Ingredients | Al2O3 Alumina Ceramic Components |

| Gas Tightness | ≤1.0*10^-11 |

| Surface Finish | Polished |

| Density | 3.9 g/cm3 |

| Dielectric Constant | 9-9.7 / 1MHz.25℃ |

| Wear Resistance | High Wear Resistance |

| Package | Carton |

| Form | Solid |

Applications:

Antaeus Alumina Ceramic Components, originating from Hunan, China, are versatile products suitable for a wide range of applications in various industries. With a minimum order quantity and pricing open for negotiation, these components offer flexibility to meet different requirements.

The Alumina Ceramic Ring is a key component known for its exceptional hardness of 9 Mohs, making it ideal for high-wear applications. Its gas tightness of ≤1.0*10^-11 ensures reliable performance in critical environments where leakage is not an option. The RoHS hardness of ≥85 further highlights its quality and compliance with industry standards.

Alumina Ceramic Plates are another offering from Antaeus, with a density of 3.9 g/cm3 providing durability and strength for various industrial processes. The supply ability is guaranteed to meet demands, ensuring a steady availability of these high-quality plates.

For more complex applications, the Alumina Ceramic Shell is a versatile choice, suitable for demanding scenarios requiring precision and reliability. The components are carefully packaged in inner vacuum packaging and outer cartons to ensure their safety during transit, with a delivery time of 15-45 days for convenience.

Customers can benefit from flexible payment terms such as T/T or negotiation, further enhancing the accessibility of these premium Alumina Ceramic Components. Whether used in manufacturing, electronics, or other industries, Antaeus products offer exceptional performance and reliability.