-

Alumina Ceramic Components

-

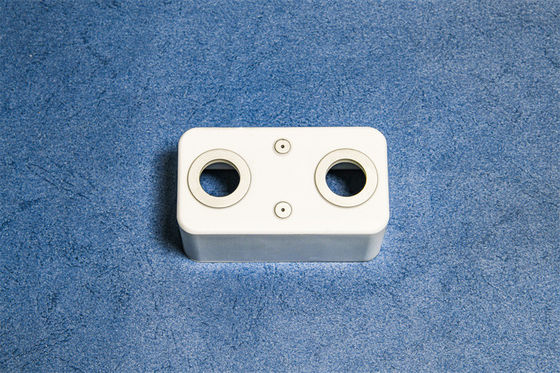

Ceramic Housing

-

Metallized Alumina Ceramics

-

Custom Ceramic Parts

-

Alumina Ceramic Insulator

-

Alumina Ceramic Rings

-

Pressure Sensor Ceramic

-

Advanced Technical Ceramics

-

Advanced Engineering Ceramics

-

Fuse Ceramic

-

Ceramic Connector Blocks

-

Electronic Ceramic Components

-

Magnetron Ceramic

-

Zirconia Ceramic Parts

-

Alumina Ceramic Rods

-

Mr.FarnReply very fast and easy to talk!

Mr.FarnReply very fast and easy to talk! -

Mr.JacksonGood service and nice to talk.

Mr.JacksonGood service and nice to talk.

Dielectric Constant 98 Alumina Ceramic Components Incorporating Al2O3 and Gas Tightness at Most 1.0 Times 10 to the Minus 11

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Thermal Expansion Coefficient | 7.5 X 10⁻⁶ /K | Dielectric Constant | 9.8 |

|---|---|---|---|

| Thermal Expansion | 7.2×10-6/K | Thermal Conductivity | 20 - 30 W/m·K |

| Tolerance | ±0.02 Mm | Breakdown Voltage | 20 KV/mm |

| Bulk Density | 3.6g/cm3-3.9g/cm3 | Thermal Shock Resistance | 250℃ |

Product Description:

Alumina Ceramic Components are engineered to meet the demanding requirements of various high-performance applications where durability, thermal stability, and precision are paramount. These components are crafted from high-purity Al2O3, which is renowned for its exceptional mechanical properties and outstanding chemical stability. The robust nature of alumina ceramic makes these components indispensable in industries such as electronics, aerospace, automotive, and manufacturing.

One of the standout features of our Alumina Ceramic Components is their impressive thermal shock resistance, rated at 250°C. This means the components can withstand rapid temperature changes without cracking or degrading, making them ideal for environments where sudden temperature fluctuations are common. Whether used as an Alumina Ceramic Pad or an Alumina Ceramic Slice, these components maintain their integrity and performance even under harsh thermal cycling conditions.

Operating at temperatures up to 1600°C, these alumina ceramic parts excel in high-temperature applications. This high operating temperature threshold ensures that the components retain their strength, hardness, and structural stability where many other materials would fail. This resilience allows for their use in furnaces, kilns, and other heat-intensive processes, providing reliable performance over extended periods.

The form of these components is solid, offering excellent mechanical strength and dimensional stability. This solid form supports a wide range of applications, from insulation pads to structural supports, and precision mounting parts. The solid nature also contributes to their excellent wear resistance and hardness, which is essential for components subjected to friction and mechanical stress.

Precision is critical in the fabrication of Alumina Ceramic Components, and our products are manufactured with a tight tolerance of ±0.02 mm. This level of precision ensures that the Alumina Ceramic Pad and Alumina Ceramic Slice fit perfectly into assemblies, minimizing the need for additional machining or adjustments. This precise tolerance also guarantees consistent performance and reliability in critical applications where accuracy is crucial.

The chemical composition of these components primarily consists of Al2O3, which is the chemical formula for alumina ceramic. This composition imparts excellent chemical inertness, making the components resistant to corrosion and chemical attack from most acids, bases, and solvents. As a result, Alumina Ceramic Components are suitable for use in chemically aggressive environments, contributing to longer service life and reduced maintenance requirements.

Our Alumina Ceramic Pad and Alumina Ceramic Slice are versatile components that can be customized to meet specific design requirements. Whether used as thermal insulators, electrical insulators, or mechanical supports, their unique combination of thermal shock resistance, high operating temperature capability, solid form, and precise tolerance makes them highly reliable and effective. These components also offer excellent electrical insulation properties, adding another layer of utility in electronic and electrical applications.

In summary, Alumina Ceramic Components made from Al2O3 provide a superior solution for applications demanding high thermal resistance, mechanical strength, and chemical stability. With thermal shock resistance up to 250°C and an operating temperature capability of up to 1600°C, these solid form components meet stringent industrial requirements. The precise tolerance of ±0.02 mm ensures excellent fit and function, while the chemical inertness guarantees durability in harsh environments. Whether in the form of an Alumina Ceramic Pad or Alumina Ceramic Slice, these components deliver outstanding performance, making them an essential choice for advanced engineering and manufacturing applications.

Features:

- Product Name: Alumina Ceramic Components

- Gas Tightness: ≤1.0×10 -11

- Thermal Shock Resistance: 250℃

- Thermal Expansion: 7.2×10 -6 /K

- Wear Resistance: High Wear Resistance

- Form: Solid

- Includes Alumina Ceramic Slice for enhanced durability

- Features Alumina Ceramic Pad for superior thermal management

- Available as Alumina Ceramic Pad with excellent wear resistance

Applications:

The Alumina Ceramic Components produced by Antaeus, originating from Hunan, China, are designed to meet the rigorous demands of various industrial applications. These components, made from high-quality Alumina (Aluminum Oxide, Al2O3), boast exceptional properties such as a breakdown voltage of 20 KV/mm and a bulk density ranging from 3.6g/cm3 to 3.9g/cm3. Available in solid form, these components include Alumina Ceramic Plates and Alumina Ceramic Slices, which are widely used due to their outstanding electrical insulation, mechanical strength, and chemical stability.

Alumina Ceramic Plates are commonly utilized in electronic and electrical industries as insulating substrates and protective barriers. Their high breakdown voltage ensures reliable insulation in high-voltage equipment, making them ideal for applications in transformers, insulators, and circuit boards. Similarly, Alumina Ceramic Slices serve as precision components in semiconductor manufacturing, providing durability and resistance to wear and corrosion in harsh environments.

In addition to electrical applications, these Alumina Ceramic Components are extensively used in mechanical and chemical processing industries. Their excellent bulk density and hardness make Alumina Ceramic Plates suitable for wear-resistant parts, cutting tools, and components exposed to high temperatures and abrasive conditions. The chemical inertness of Alumina (Al2O3) ensures that these components maintain performance without degradation in corrosive environments, which is critical in chemical reactors and laboratory equipment.

Antaeus offers flexible purchasing options with a minimum order quantity negotiable to suit customer requirements. The pricing is also negotiable, ensuring cost-effective solutions for bulk or custom orders. Each product is carefully packaged using inner vacuum packaging and outer cartons to maintain integrity during transportation. Delivery times range from 15 to 45 days, depending on order specifications, with payment terms including T/T or negotiation to accommodate various business practices.

With a full supply capability, Antaeus ensures consistent availability of Alumina Ceramic Plates and Alumina Ceramic Slices to support continuous production needs. Whether for electronic insulation, mechanical protection, or chemical resistance, these Alumina Ceramic Components demonstrate superior performance and reliability across a wide range of application occasions and scenarios.

Customization:

Antaeus offers customized Alumina Ceramic Components including Alumina Ceramic Slice, Alumina Ceramic Pad, and Alumina Ceramic Plate, designed to meet your specific requirements. Manufactured in Hunan, China, our products feature high wear resistance and excellent thermal shock resistance up to 250℃, ensuring durability and reliability in demanding applications.

Our Alumina Ceramic Components have a dielectric constant of 9.8 and a thermal expansion coefficient of 7.5 × 10⁻⁶ /K, with thermal expansion rated at 7.2×10⁻⁶/K, making them ideal for various industrial uses. We provide flexible customization options with a minimum order quantity negotiable to suit your project needs.

Pricing is available upon negotiation to deliver the best value for your investment. All components are carefully packaged with inner vacuum packaging and an outer carton to ensure safe delivery. Antaeus guarantees full supply ability with delivery times ranging from 15 to 45 days.

Payment terms are flexible, accepting T/T or other negotiated methods. Choose Antaeus for premium quality Alumina Ceramic Slice, Alumina Ceramic Pad, and Alumina Ceramic Plate with tailored services to enhance your product performance.